Die Casting Mold: How it works and its particular advantages

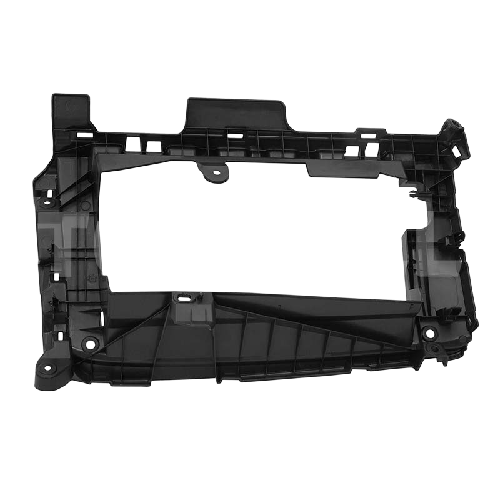

Die casting mold is truly a device that is special in manufacturing various objects with molten steel being poured associated with it. Topwell die casting really is a manufacturing technique involving creating an mildew this is certainly accurate of product to then be manufactured filling it with molten steel under some pressure.

Advantages of Die Casting Mold

One benefit of Die Casting Mold is its efficiency in producing large volumes of complex steel parts with high rate and precision. That is an operation that will create parts with complex forms and features which are detailed keeping in your mind what exactly is needed and specs related to client. Furthermore, the amount is paid down because of it waste produced during production, making the Topwell die cast metal process cost-effective.

-

Innovation in Die Casting Mold

Aided by the advancements in technology, die casting mold has undergone an alteration, certainly manufacturing that is significant, product innovations, and design elements. The growth within the utilization of CAD and CAE has made a effect this is significant developing services that are geometrically complex products. Topwell aluminium die casting provides be economical and practical to utilize aluminum and zinc alloys when compared to other metals like iron and metal. The utilization of brand new materials in creating and constructing molds are its durability and cost-effectiveness.

-

Safety precautions in Die Casting Mold

Manufacturers make certain that security precautions are found whenever using die casting molds. Any injury brought on by using a Topwell permanent die casting can long be avoided as as the operator keeps vigilance in monitoring the process. Protective gears such as goggles, gloves, along with other security gear, will also be supplied to ensure the security about the operator.

-

How to Take Advantage Of Die Casting Mold?

First, the item design is prepared using design computer software this is certainly computer-aided (CAD). Then a design is translated as a die casting mold utilizing CAM or production pc software or computer-aided. Following the design is actually examined and approved, the mold shall be produced, and molten metal is poured a part of it. This system shall be taken from the molding utilizing hydraulic or pneumatic stress. The Topwell centrifugal die casting is then further processed to refine the top, as well as add details that can be finishing.

Comments

Post a Comment